Back at college and it seems like we’ve been away for ages. Been looking forward very much to getting back in front of the workbench and getting on with this little cabinet. Here’s how things went today.

Back at college and it seems like we’ve been away for ages. Been looking forward very much to getting back in front of the workbench and getting on with this little cabinet. Here’s how things went today.

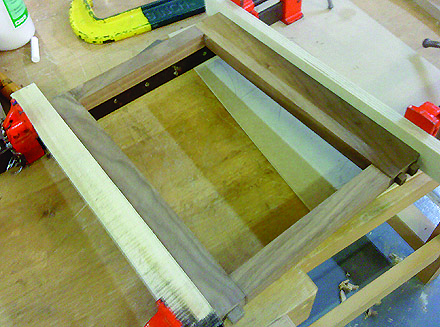

Good day today. I cut down the shelf which will sit inside the cabinet, and will finish trimming the size on the next day. The bottom rails are both in, so once any odd surfaces are planed to fit, this cabinet can be glued up and I can move onto the final part, the dovetailed drawer.

We finished this year with a good few drinks in a Whitechapel pub round the corner. Conversation covered walks that takes in Dicken’s’ landmarks mentioned in ‘Great Expectations’. Heirloom pieces of furniture, ie are people now buying for quality and craftsmanship, rather than just for low price? And general chat about violins, with the instrument makers who also take up a part of the college’s space. I’ve always wanted to make a violin, perhaps that should be my next course?

Merry Christmas to one and all. Thanks for reading!

Day 9! Sort of unbelievable how quickly the time goes, I’m about two-thirds through my course. I’m really enjoying learning about casework and the myriad of details that have to be considered. Anyway, here’s the progress on my little cabinet, for those who are interested. Click the pic for the jump.

Feels like time is fast running out to get this little cabinet up and on it’s legs, but hopefully it will be standing by next week.

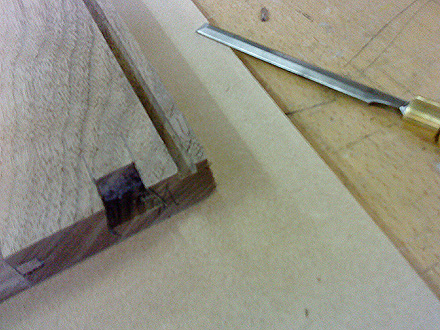

I did quite a bit on the connecting rails this week, to join one side panel to the other, but spent the rest of the time smoothing the panels with a nice ‘Millers Falls No.18‘ bench plane.

This plane came in a job lot of tools I bought from a gentleman in Romford last week. A fascinating chap, who used to be a pattern maker for the Ford Motor Company in Dagenham. We spent a good couple of hours chatting and he did me a great deal on a bunch of nice tools.

I ended up selling the plane to a colleague on the course who likes Millers Falls, as I already have a large Stanley jointer, and a Stanley 4 1/2. During the course of the day, Alex sharpened up the iron on the Tormek and got the plane cleaned up. I was lucky enough to have a go with it on my cabinet, and I have to say, it was one of the nicest planes I’ve used. It had a really good heft to it, and with the razor sharp blade, was taking fantastic shavings.

Think I’ll end up looking for another one of these at some point. Millers Falls have been on my radar for a long time, but being US-made, whenever I see one for sale, I usually get put off by shipping charges. Quite how this one ended up being used by a craftsman in Romford, I don’t know. I should have asked!