It’s nice to have a moment to write a blog post, it’s been way too long.

I won’t bore you with the details, but the house renovation I’ve been working on has taken much longer than I thought it would, mainly because I get there only for one or two days in the week.

I’m finally onto some joinery however, having finished with all the ‘wet trades’ long ago. The electrician had a final visit last week and from this Monday, the plumbing will all be done with too.

I’ve turned my attention to some Shaker-style doors I’ve been meaning to make for a long while for the bedroom cupboards.

As I’m trying to finish as fast as I can now, I figured I may as well invest in some Festool power tools. I bought the TS55 track saw from a friend a while back and this week added a Domino DF500.

If you don’t know the Domino, it’s a nice tool for cutting mortises which Festool’s own ‘Dominos’ fit into. It’s basically a fast way of making a loose tenon. The machine works very well and I had the doors made in no time.

If I did have a problem, it’s with the saw. The TS55 seems to be holding back by 1-2 degrees when it should be full open at 90 degrees. It’s annoying as it means when you crosscut for a Domino joint, the joint has a tiny gap when you Domino it. Then when you join and glue, the pressure from your clamps pushes the joint out of shape.

If anyone has details about how I can fix this saw issue, can you please let me know?

I have already fiddled with the two silver adjustment screws, and I thought I had pulled the base plate in enough to make it perpendicular to the blade. But when I used the saw again today, same problem, the cuts weren’t straight.

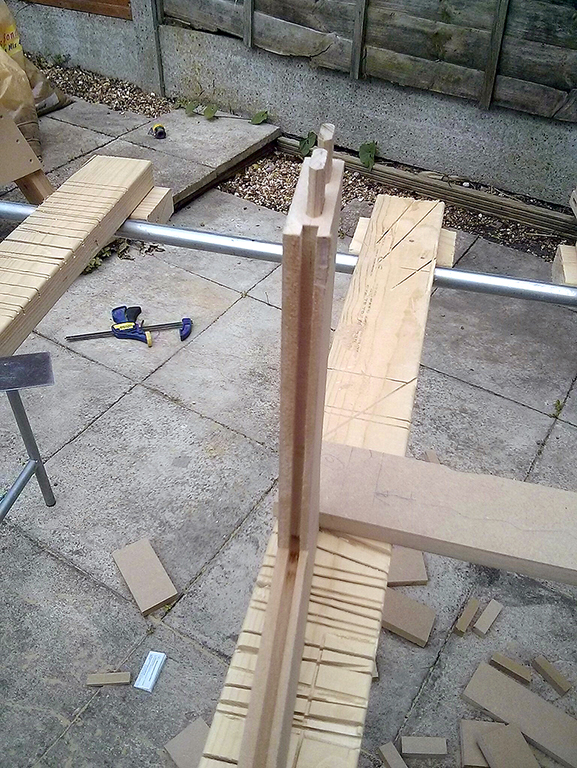

The pic below is how the blade looks when the saw is fully open. (I can’t hear a click or anything else to suggest I should move the saw back a degree or so, for me, it’s useless if it doesn’t click to exactly 90 degrees.

Category: Festool

All too soon, here I am. The final day of my short course at John Cass. Lots to do today, and I have to finish this cabinet, what with having nowhere to work at home. Onward.