The picture at the head of this post shows the GWR (Great Western Railway) Carriage Erecting Shop at the Swindon Works in 1886. Look closely and you will see the craftsmen’s tool chests positioned between each workbench. One of these chests was recently offered to me as a restoration project and it still has some original tools left in it. The chest is pretty battered, but with some careful replacement of parts to the tills and sliding drawers, would not be a huge job. If you are interested in saving this wonderful old chest, get in touch. I don’t have the space for the project and I already have a similar chest which I use. If I do complete a sale, I’m happy to pass the chest on, (probably minus the tools), without any profit for myself. Tool chests like these deserve to be saved.

Britain was hugely affected by the advent of the railways in the first half of the nineteenth century. The GWR completed it’s first section of line from London’s Paddington station to Maidenhead in 1838. By the end of 1840, the line extended through Swindon, with the line being completed out to Bristol in the summer of the 1840.

The Engineer to the Company was none other than, of course, the great Isambard Kingdom Brunel. Brunel and his Superintendent of Locomotives, Daniel Gooch, were concerned about the poor quality of locomotives being supplied by outside contractors and resolved to set up a central repair depot for the rolling stock.

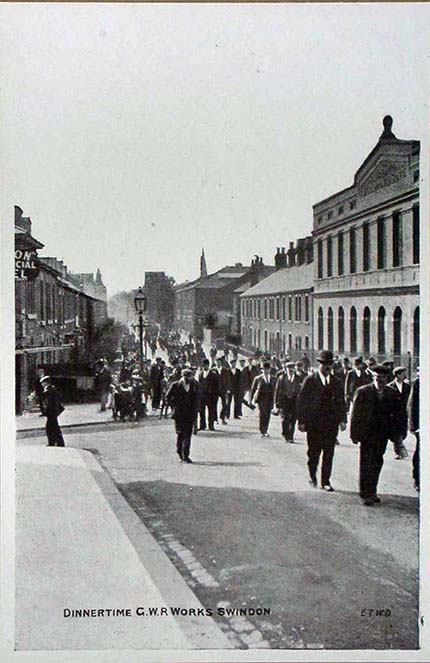

The chosen location was Swindon, which afforded direct connection to the Somerset coalfields via canal and well placed with it already being at the junction of the Cheltenham branch. Work began in 1841 and within two years the works employed 400 men, including 72 highly-skilled engineers. The workers made it quickly clear that they wanted to take on ‘in-house’ manufacturing also, and in 1846, the company produced its first locomotive, called the Great Western. From 1861 they even started making the rails in Swindon’s own mill.

Battles over the costs of all this innovation saw Gooch resign after one too many arguments with company directors, but he was swiftly re-hired as chairman of the company later on, perhaps with the directors realising just how important innovative ideas were in their business.

One battle that the GWR was losing, however, was over the railway gauge, with Brunel’s broad gauge about to be superseded by standard gauge. Swindon produced its first standard gauge locomotive in 1855 and until the final conversion nearly forty years later, Swindon gave birth to engines of both types.

In 1867 Swindon Works expanded still further when the company decided to build its new carriage and wagon works there, which was completed in 1868. The final conversion from broad to standard gauge took place with a mammoth feat of engineering on 21st and 22nd May, 1892 and thirteen extra miles of sidings were laid down as 195 locomotives, 748 carriages and 3,400 wagons and vans lined up for breaking up or conversion to the new gauge.

Expansion continued, with new locomotives being designed and the Works managed to get through WW1 and out the other side. 1920 saw what was probably the high point of the company, with the huge new ‘A’ shop being completed, covering 11.25 acres and employing 14,000 people.

George Jackson Churchward, Carriage and Wagon Superintendent (later Chief Mechanical Engineer in 1916), was succeeded by Charles Benjamin Collett (1921-1941) and Frederick William Hawksworth (1941-1949). The first Castle Class locomotives were built in 1923 (Caerphilly Castle, number 4073) but even these were overshadowed by the colossal King Class, the flagships of the GWR, of which King George V (number 6000), built in 1927, remains the most famous. The workhorse Hall Class locomotives followed in 1928 as the GWR in general and Swindon in particular enjoyed an international reputation for engineering excellence for the rest of the pre-Second World War period.

When Britain’s railways were nationalised on January, 1948, the GWR history ended. The final blast of the Works hooter sounded for the last time on 26th March, 1986.